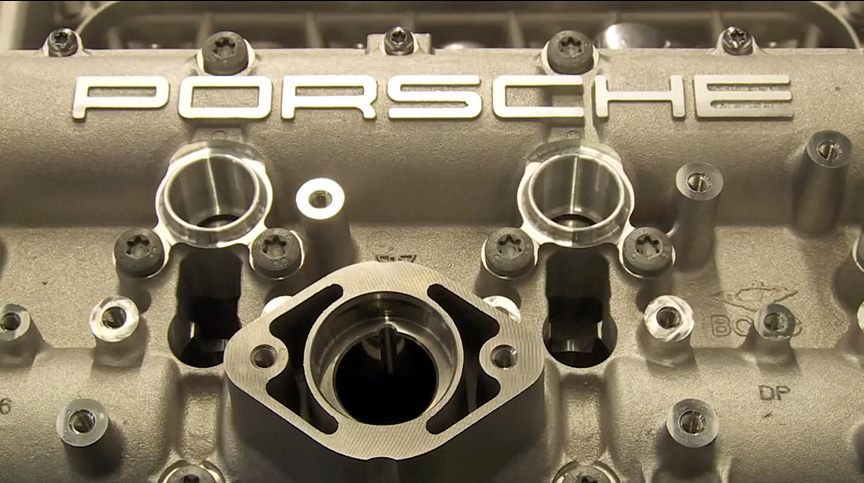

The Making of the Porsche 918

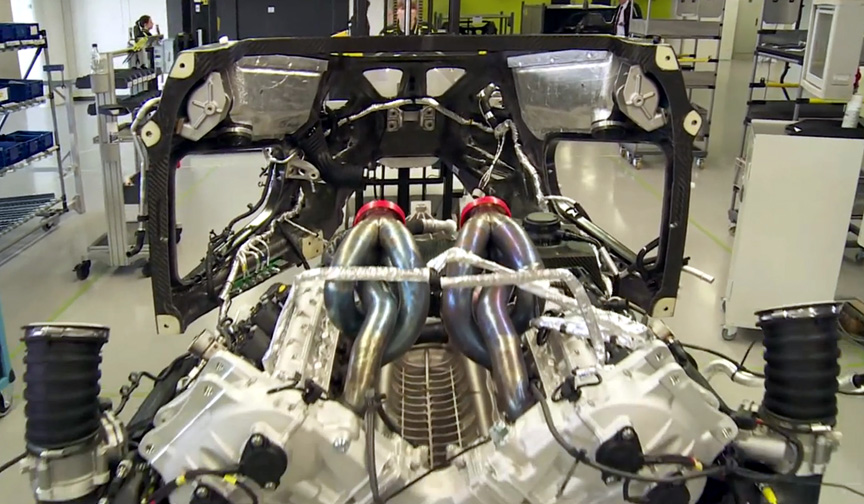

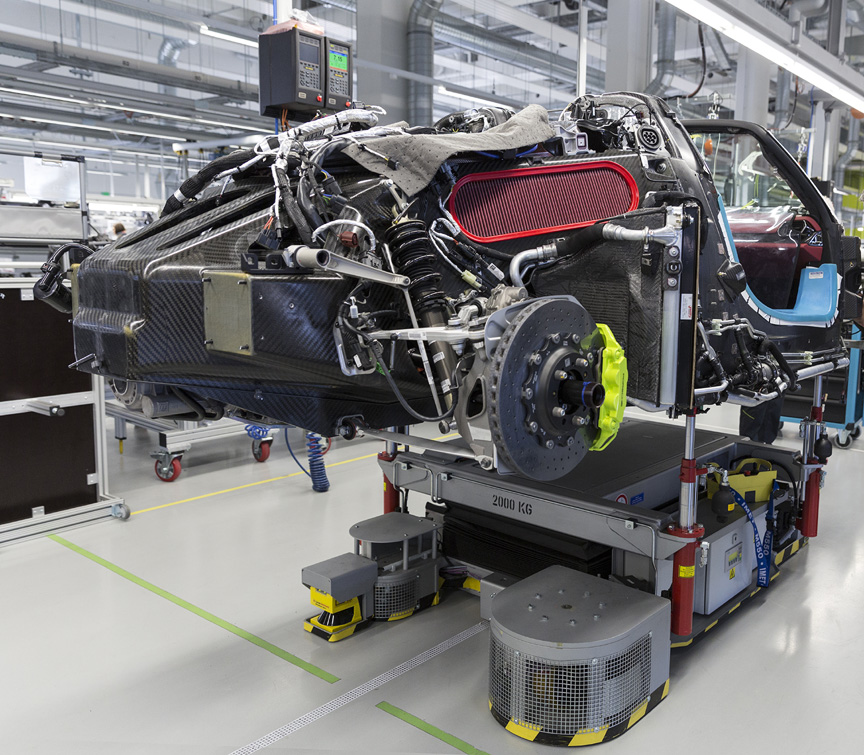

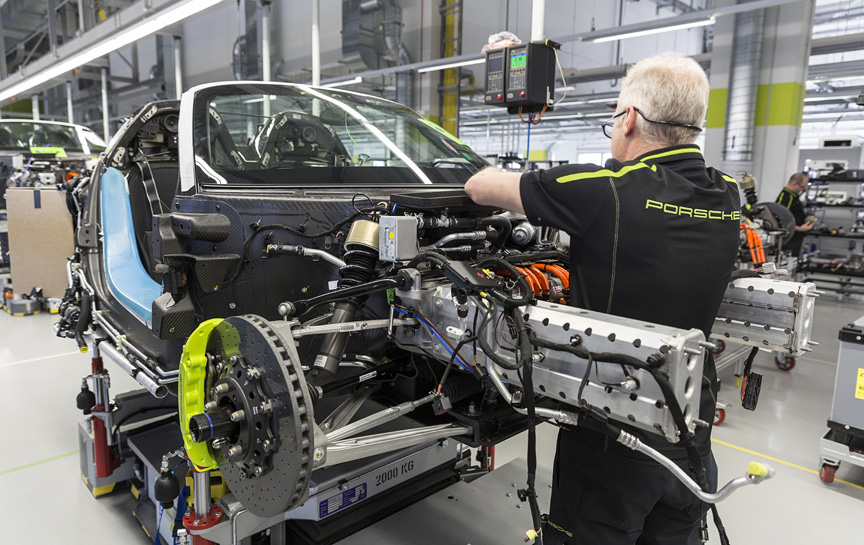

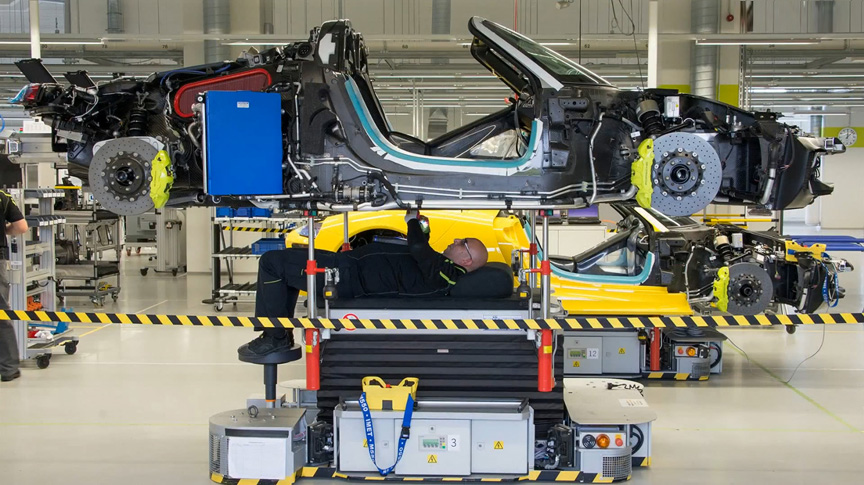

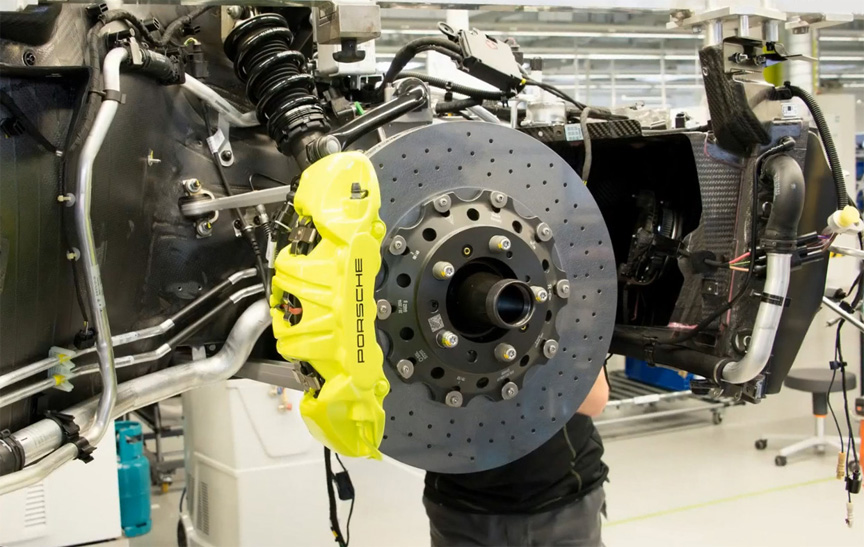

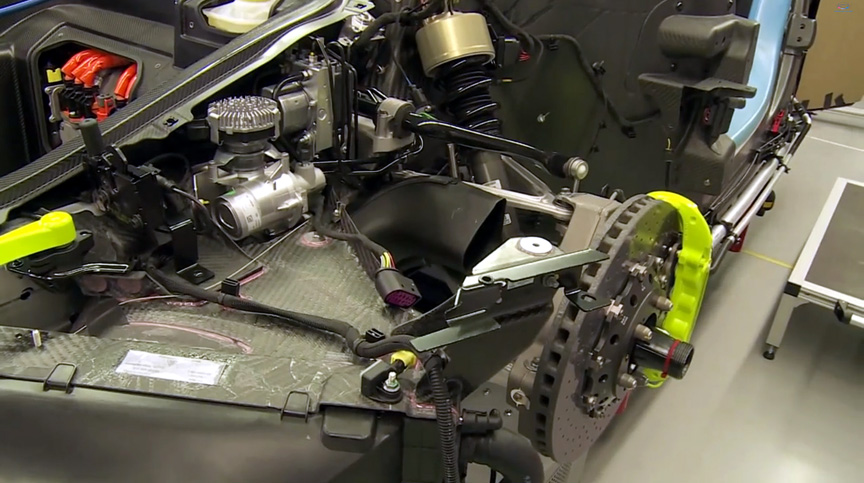

Strictly limited to just 918 units and assembled in a 4000-square-metre manufactory by 100 selected employees by hand. Take a look at this footage from the birthplace of the 918 Spyder in Zuffenhausen, Germany.

Porsche 918 Manufacturing Details