The new Porsche Cayenne, a superb example of leading-edge software integration, owes its performance and customer experience to the expertise of Porsche Engineering. In collaboration with Porsche and its suppliers, Porsche Engineering has developed large parts of the propulsion system and chassis, incorporating innovative hardware and customized software to deliver the industry-setting “Porsche driving experience.”

Focus on System Integration

“One of our central tasks is system integration,” says Eva-Verena Ziegahn, Director of Drive System at Porsche Engineering. “This includes the implementation of code in ECUs as well as the calibration and validation of new functions.” Porsche Engineering took charge of numerous development scopes while work was progressing on the Porsche Cayenne. From the beginning, the seamless integration of hardware and software was the focus for the propulsion system and chassis. “The Cayenne is characterized by the wide spectrum of driving comfort and sportiness,” explains Ziegahn. “This is achieved, for example, in the case of active anti-roll stabilization, through innovative software and parameterization as well as integration into the overall chassis. In the process, we have to factor in the complex interactions in the chassis, where all-wheel drive, front and rear-axle steering, the brake system, and the electric drive influence the driving experience.”

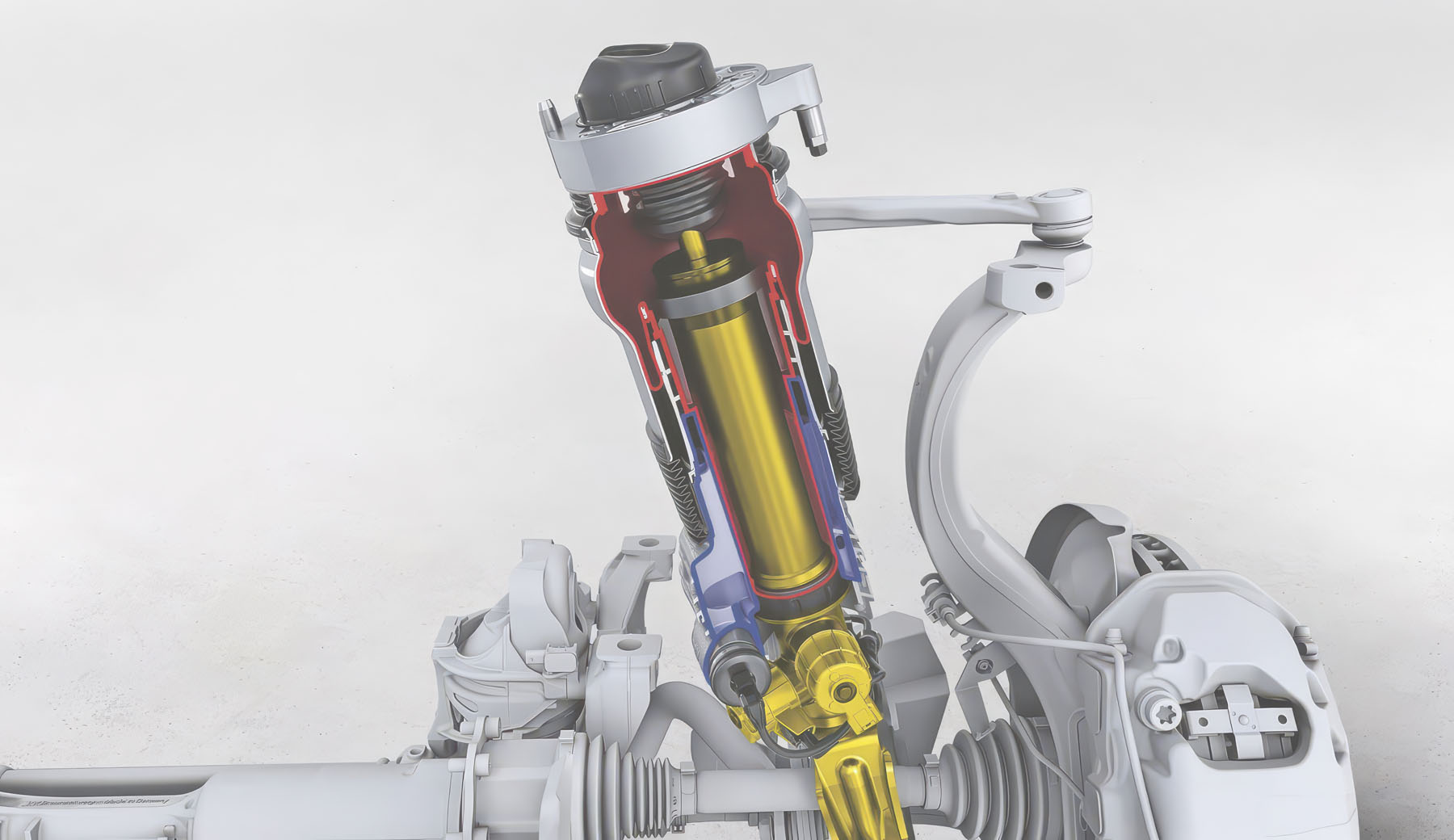

2-valve Damper Technology

Ziegahn calls the development and calibration of an innovative system in the chassis an example of successful interaction between hardware and software: Dampers with 2-valve technology and separate rebound and compression stages are being used for the first time in the luxury SUV. Developed by Porsche Engineering together with a supplier, they allow a broader spectrum between sporty and comfortable driving, resulting in optimized performance in all driving situations. The innovative hardware also made a notable difference when it came to the requirements for software development: “Due to the new 2-valve dampers, the controller components had to be changed, and new interfaces to the basic software had to be defined,” as Fabian Heitkamp reports, development engineer at Porsche and responsible for the electric chassis platform (EFP). “Moreover, there was only a little we were able to adopt from the previous version for the control unit and the basic software. In short: No stone has been left unturned.”

Chasing the perfect brake pedal feel

The developers also focused on the interaction between hardware and software for the brake system for the new Cayenne. Their task: The driver should have the best possible pedal feel and should not be able to perceive the respective share of the hydraulic friction brake and the share of the electric motor in vehicle deceleration. The regeneration function is responsible for this ‘blending’ between the hydraulic friction brake and recuperative braking. The exact composition of this mix depends on numerous factors. “Basically, our goal is to use recuperative braking as much as possible, thereby reducing the average energy requirements of the vehicle as much as possible and thus, among other things, increasing the electric range of the vehicle,” explains Lisa Helbig, Development Engineer for Brake and Steering Systems at Porsche Engineering. “The hydraulic friction brake comes into play, for example, when the deceleration of the electric motor is insufficient or when the vehicle could become unstable due to regeneration on the rear axle.”

The interconnected software components of the brake system also helps to compensate for changing characteristics of the friction brake in the best possible way. Both the temperature and the wear on the brake over time are taken into account. One particular challenge is that the algorithms run on different control units, which is why the software for the braking system could only be applied to the overall system of control units. While the software for the eBKV originated from a supplier, Porsche Engineering handled the calibration of the functions and their testing. The final step was the approval of the vehicles together with Porsche.

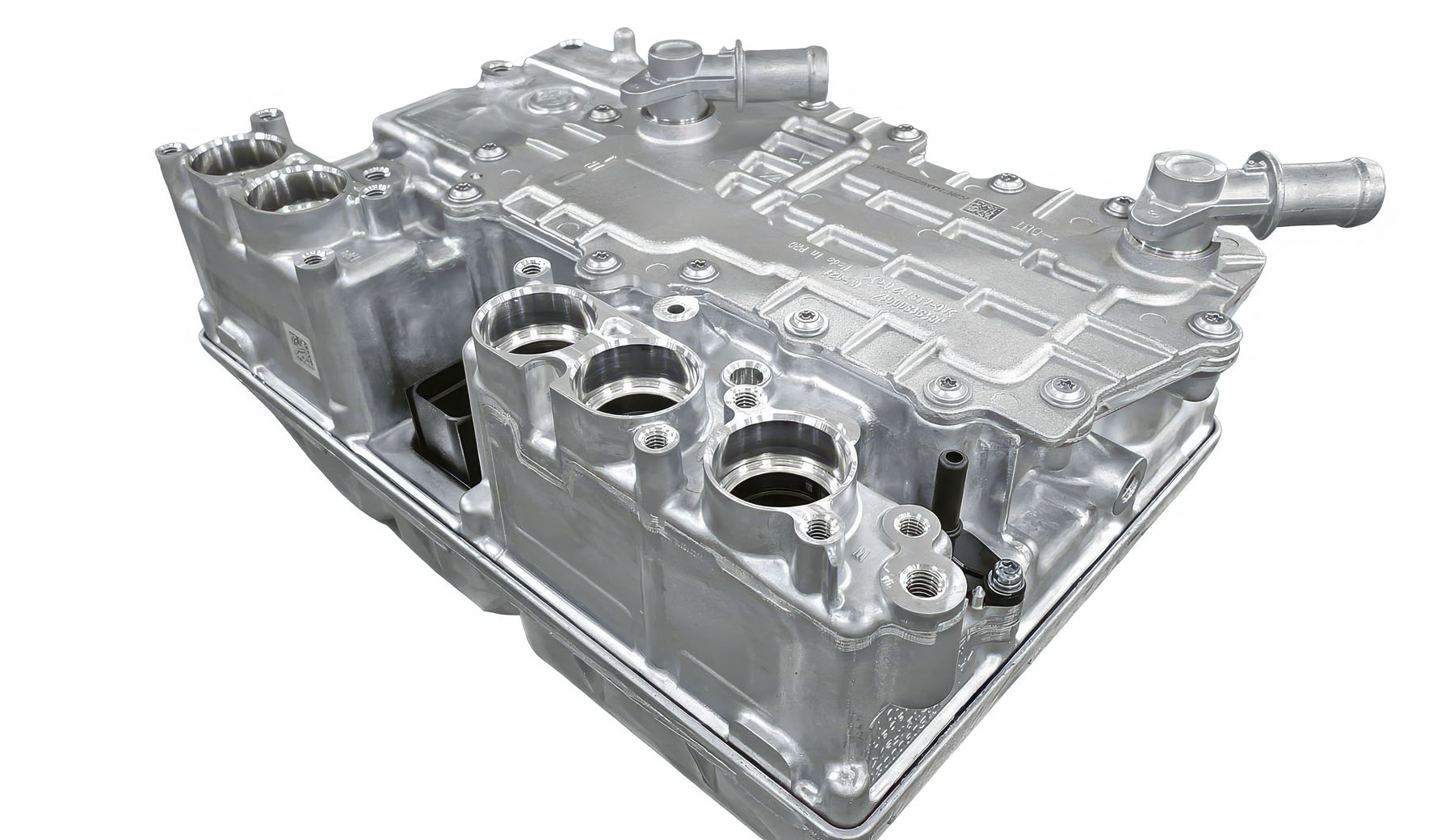

Noise suppresses Noise

In addition to the new damper system and the hybrid brake, Porsche Engineering was also involved in developing, testing, and validating the pulse inverter (PWR) for the new Cayenne from the beginning. In this case, the main thing was to make the transition from the combustion engine to the electric motor imperceptible to the driver while at the same time enhancing the vehicle’s performance. Among other characteristics, the newly developed pulse inverter is characterized by a variable switching frequency and different modulation methods optimized according to the current operating point. “Reducing the pulse frequency of the pulse inverter increases its efficiency, enabling a ten percent boost in the power output of the motor—only through intelligent control via software,” explains Pascal Heusler, Senior Manager Pulse Inverter Software and Calibration at Porsche. “This has a drawback in terms of noise. However, because this approach produces noise. The solution to this is to generate an artificial noise around the carrier frequency, which dilutes this motor noise.”

However, this approach cannot be applied to every operating point. The idea: The controller must react within a few milliseconds and adjust the switching frequency if necessary. “It’s a very innovative solution,” says Heusler. “We improve the system efficiency and at the same time ensure that with the sophisticated sound composition, the driver doesn’t hear a thing.”

The pulse inverter in the new Cayenne is used as a modular system throughout the VW Group—the same control unit is used in almost 100 different vehicle variants that use five different electric motors and three different transmissions. In addition, they are based on different platforms—either the new Volkswagen E3 electronics architecture or MLBevo. So system integration in this case also meant integration across different brands and vehicle classes, which the developers succeeded in doing. “From the outside, the variants can only be distinguished by their different connectors; the inner parts are always the same,” as Frank Deckert, Project Manager for Pulse Inverter Integration at Porsche Engineering. “We covered the entire variance with a single piece of hardware.”

Above content © 2024 Dr. Ing. h.c. F. Porsche AG reviewed and edited by Rex McAfee