If there is one thing in a car that most people don’t pay any mind to that is a critical safety system, it’s their brakes. Think about it before your next drive, as you’re going down the freeway at 70 MPH, and the only thing keeping you from hitting anything is a hydraulic system that actuates pads that squeeze against either metal or carbon ceramic discs. It truly is mind-shattering how much we rely on those brakes, and how the technology developed over the past century and a quarter of automotive history has made them from something that was a good idea to a powerful, critical safety system.

There is, however, a new style of braking system out there with the rise of EV’s, and one of the most advanced systems is installed in Porsche’s own Taycan electric sports car. Along the same line as the development of brakes, but compressed to just about 20 years, regenerative braking has gone from being a good idea, to being implemented in motorsport, developed for the road, and almost every electric car on sale today will use it. But what, really, is so special about Porsche’s braking system?

Not As Simple As It Seems: Regenerative + Hydraulic

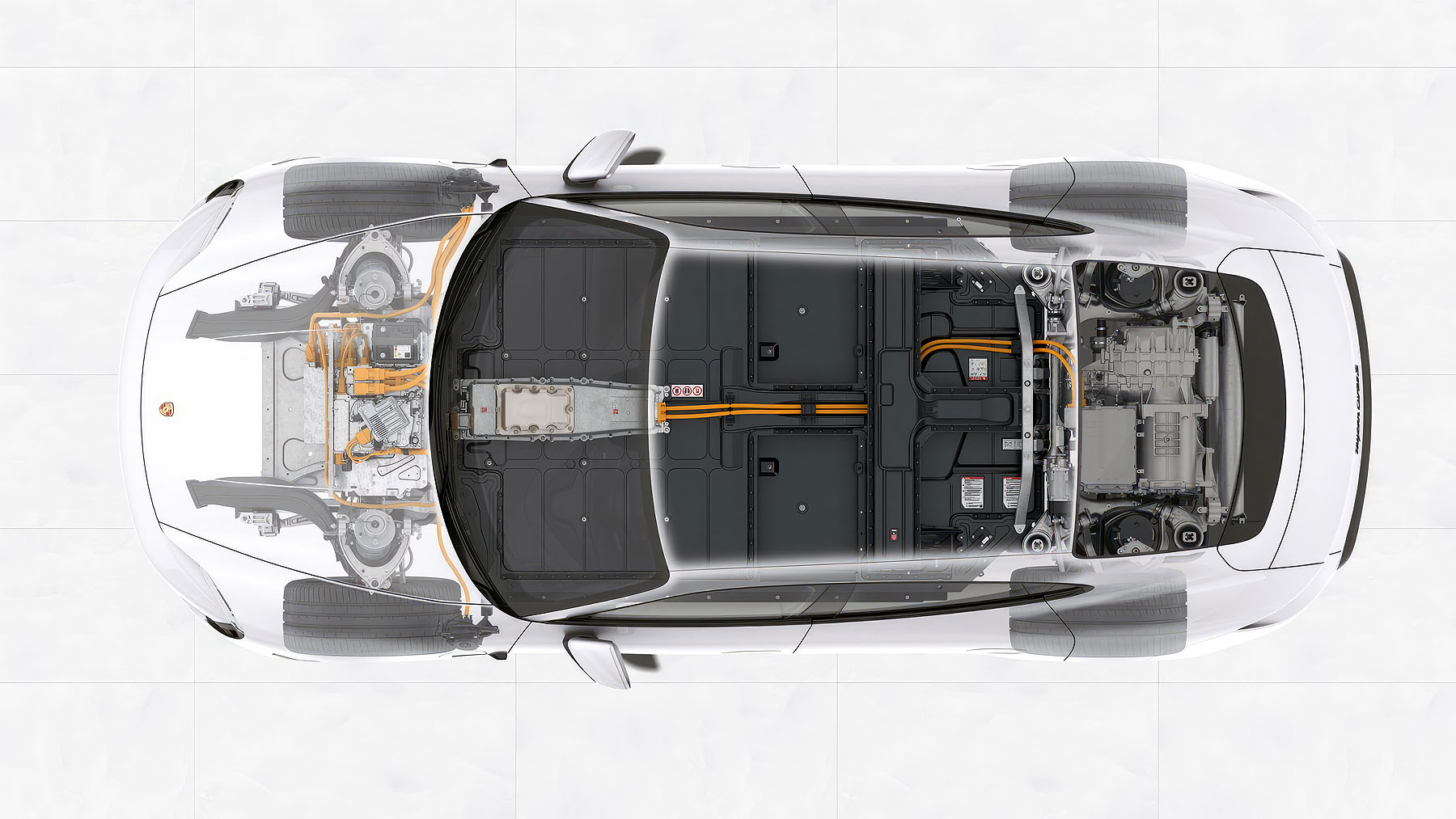

The first thing to consider about electric vehicles is that despite being made out of lightweight materials and using the latest and greatest battery technologies, they, quite simply, are heavy. Consider that a 2022 Porsche Taycan S weighs just about 4,770 lbs (~2,160 kg), while a Panamera, which is about the same size as a Taycan S, weighs closer to 4,100 lbs (~1,860 kg) on average. That is a significant amount of extra weight to slow down, and to do it without needing to give the car 22 inch brake discs, the engineers and designers of the Taycan looked to motorsport.

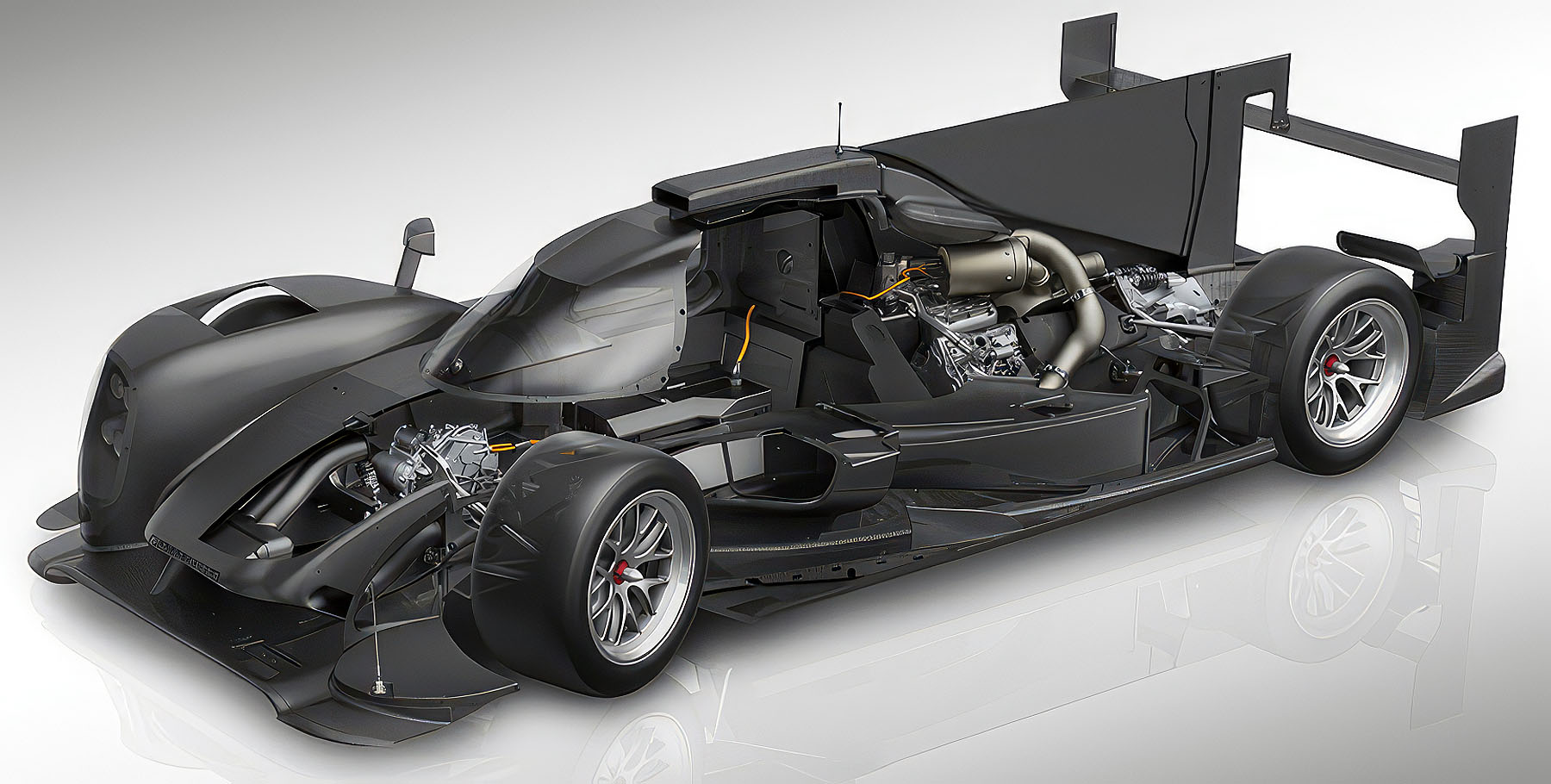

We all know of the Porsche 919 Hybrid LMP1 race car, as it dominated in endurance racing, as well as the 918 Spyder, which makes up one third of the “Holy Trinity of Hypercars.” The truth of the matter is that the two projects, for a long time, were worked on in the same building, with the desks of their teams literally side by side. As well, at the time they were being developed, Formula One had just started to use the Kinetic Energy Recovery System, or KERS, to give the V8 engines in the cars at the time a driver-commanded electric boost in power every lap for a few seconds. It was in both of these cars, using a Porsche-engineered version of KERS, that the first regenerative braking system came to be from Stuttgart.

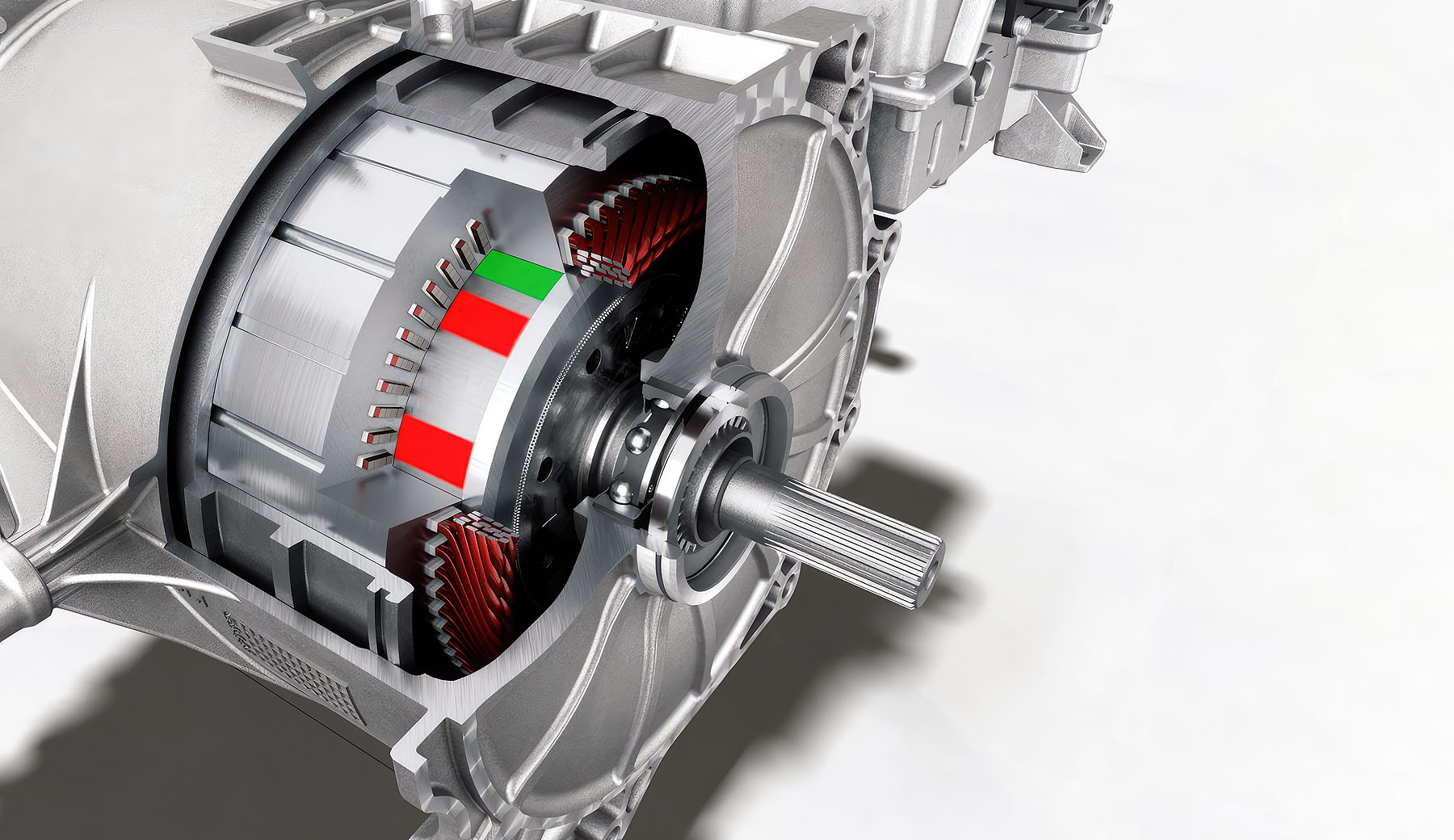

It works, as do most regenerative braking systems, through the concept of electromagnetism in physics. Put a charge through a wire coiled around an insulator, with a smaller coil on an axle inside that outer coil, and the magnetic field generated by the current through the wire pushes that inner coil, creating thrust. Turn that current off, however, with the inner coil still spinning at speed, and the outer coil is suddenly receiving a charge. It’s the same “basic” idea as hydroelectric power generation, except comparatively minuscule in scale.

To simplify it even further, think of it as the accelerator and brake pedal in the Taycan. Push the accelerator, power flows from the batteries around the coils, and you accelerate, the motors driving the wheels. Press the brake pedal, the system flips, and it’s now the wheels driving the motors. Yet, while this effect is quite strong, it is not enough on its own to brake a 2.4 ton car when you step both feet on the brakes.

That’s where the other braking system comes in, our familiar disc brakes with their hydraulically operated calipers. But, much like with the race car and the hypercar, how do the two work together?

How The Taycan Figures Out Which System To Use

A Very Complex Choreography Timed In Milliseconds

The Taycan is one of the most advanced electrical vehicles out there. Not a boast, not a claim to fame, it’s just a simple statement of fact. It has multiple computers on board, each figuring out aspects of the car, driver, driver inputs, sensor readings, and a thousand other things, thousands of times per second. There is, however, a computer that is solely and completely dedicated to braking.

The reason for this is that while the brakes are controlled by hydraulic master cylinders, those cylinders, unlike internal combustion powered cars, are not directly connected to the brake pedal. Instead, the Taycan uses what is known as “Brake by wire,” in which that dedicated braking computer calculates the amount the pedal has been depressed, and according to Porsche themselves, 90% of the time, the electric motors are producing enough decelerative force to effectively brake the car.

To amplify the braking effect, the braking computer has several options to select. It can flow a small bit of electricity “the wrong way” around the wires in the motors, using magnetism to slow the axle down faster, or it can apply the hydraulic brakes (calipers and discs) as needed. This dance happens thousands of times per second, and 99% of the time, all you will feel is smooth, progressive deceleration as the car does the heavy duty footwork for you.

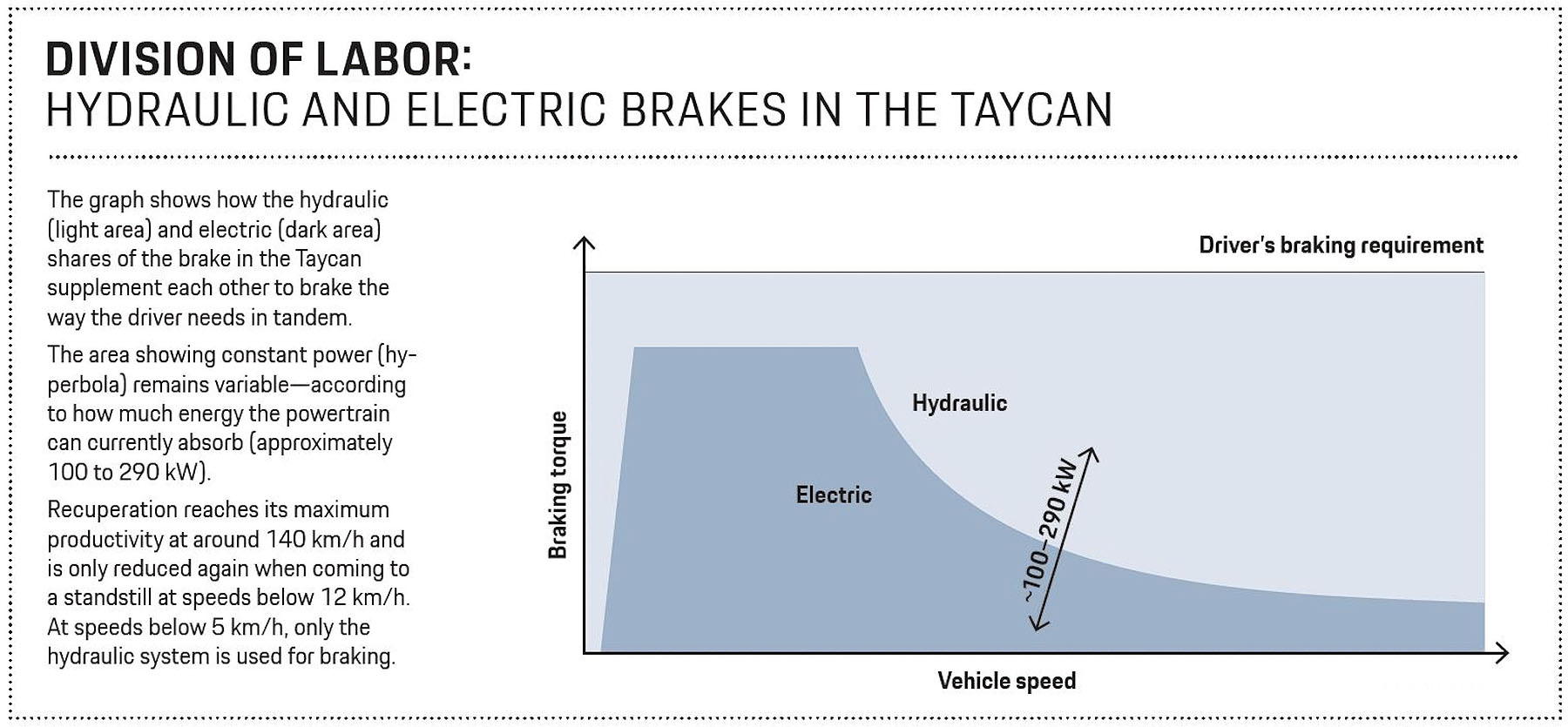

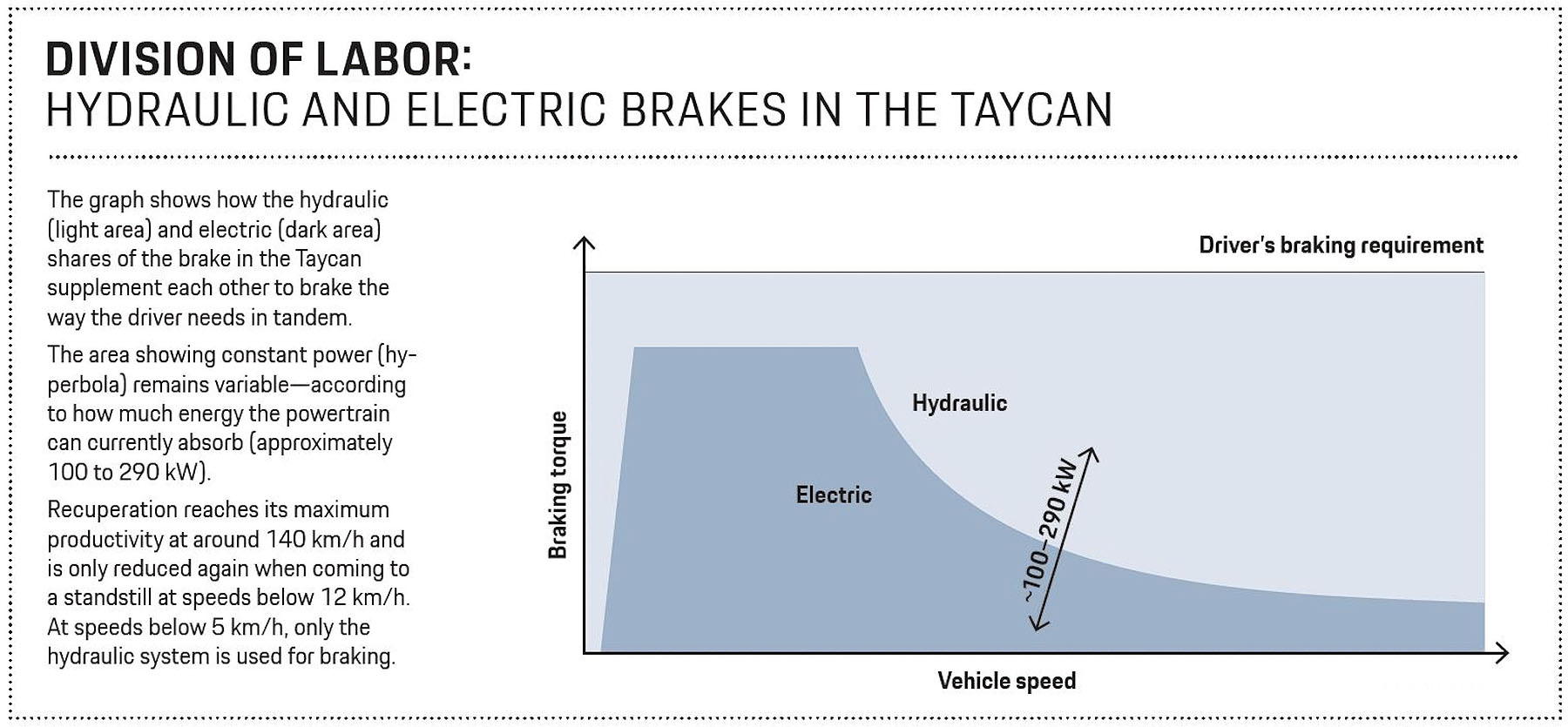

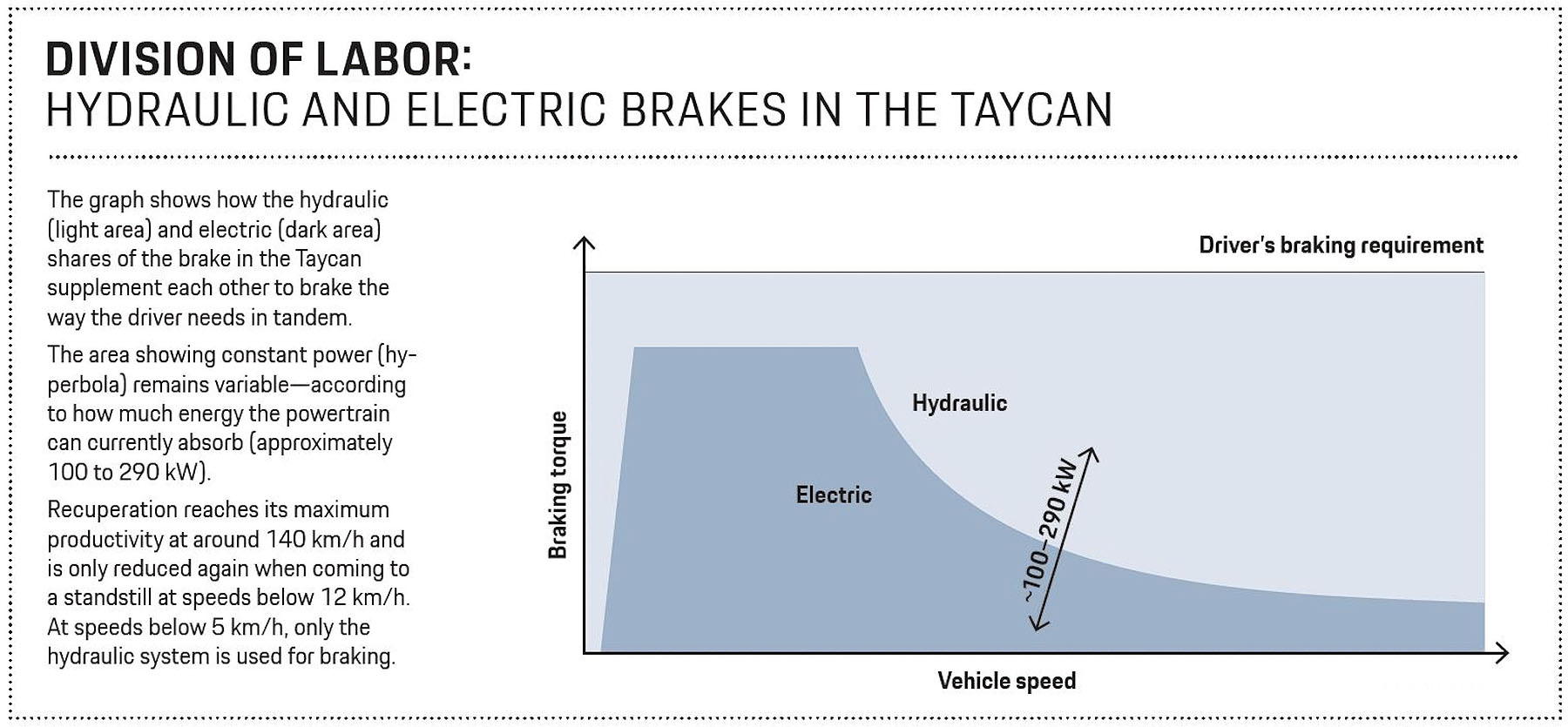

To give you an idea of just how strong that regenerative braking is, during braking from 70 MPH to a stop, the Taycan can produce 290 kW of electrical power, all of which is shoved back into the batteries. The average American household, two adults, two children/teens, and all of the modern electrical devices located within, uses about 30 kW of energy every half hour. In essence, when you press the brakes in the Taycan, you are generating enough electricity to run your home, if you unplugged a few things, for a good 5 hours.

However, there are times when the computer will read that despite the brake pedal being depressed rather strongly, and the motors in full regenerative braking mode with that little reverse current boost, the car is not slowing down at the rate demanded, and within a hundredth of a second, will actuate the hydraulic brakes as well, while still keeping control of them as that computer also controls the ABS system.

The Porsche Difference: A Complex Algorithm That Makes Things Seamless

What makes the Taycan so special with its regenerative braking is a newer technology and algorithm, pioneered by Porsche, that has taken on the name of “blending.” The entire concept is built on the fact that in the 918, and even the 919 race car, the driver could feel when the hydraulic brakes were used, and when the regenerative brakes were used, and it could be disconcerting if you were not used to it. With blending, the design goal was to smooth out any transition, or addition, of braking power to the point that it is imperceptible to the driver.

Porsche also emphatically states that they are not going down the path of “one pedal driving,” which brakes automatically if a driver lifts off the accelerator pedal and uses sensors to detect how much and how hard to brake. The driver is a key component of every Porsche car, an integral component of the complex machinery that causes the bioelectric commands in your body to lift the corners of your mouth and pull your cheeks back slightly to produce a smile.

As part of this, regenerative braking doesn’t begin until the brake pedal is touched. If you accelerate a Taycan, and then lift your feet off and away from the pedals, the car will simply coast along as if you put the gear stick in a 911 into the neutral position. Of course, being Germans, the whole idea behind coasting for Porsche is efficiency, as it is far more efficient to let gravity and inertia do some of the work, as the kinetic energy already applied to the car keeps it rolling.

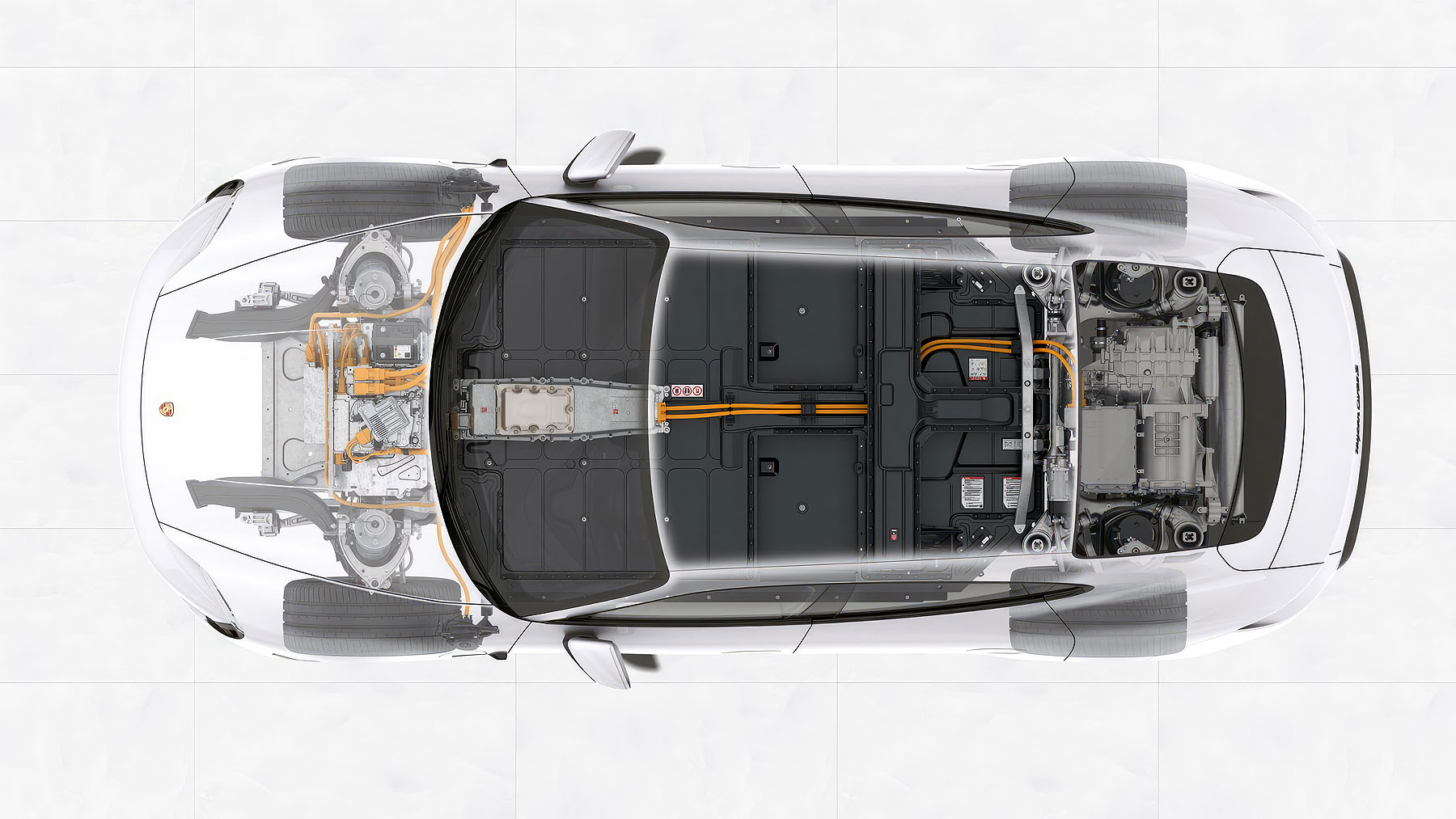

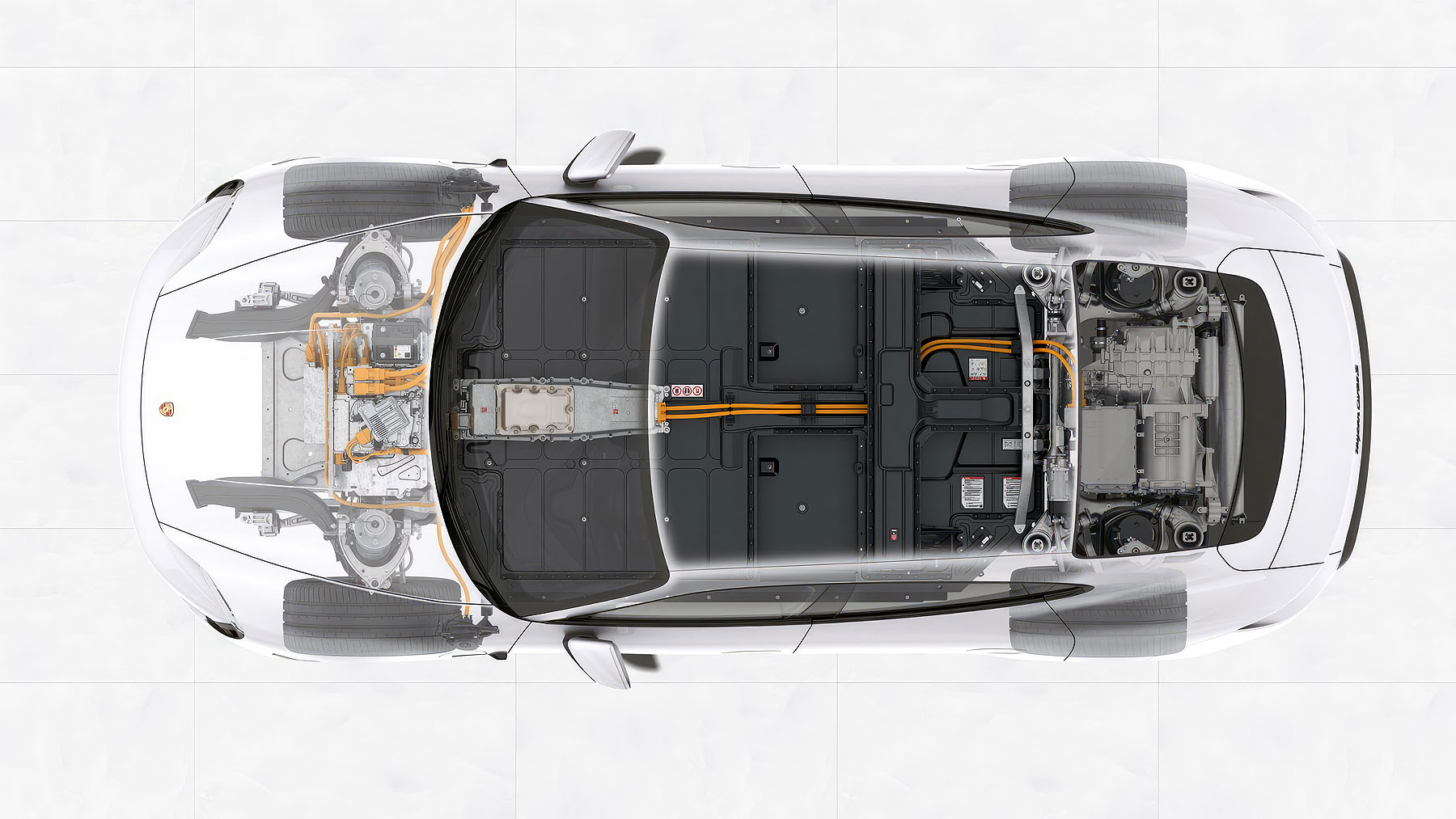

The recovery of that kinetic energy is driver commanded through the pedal, but only to the point of turning on the recovery system. By constantly adjusting the braking force with the level of force the driver is pushing the brake pedal with, the blending system uses either, or both, brakes to slow and stop a Taycan. Another technological aspect that was in the 919 race car that helps with braking is known as eBFD, or electrical Brake Force Distribution.

Most electric cars will have one, maybe two, rarely three, and only on really expensive ones four electrical motors. The more motors you have in an EV, with the Taycan having two, the more effective “brakes” you have. Porsche has developed their regenerative braking to be constantly variable, such as applying more regenerative braking to the rear if the car senses you are headed up a hill, or almost all of it to the front axle if you slam on the brakes to slow down quickly. It’s constantly shifting where the braking force is applied, and in emergency situations, it also will independently control each hydraulic brake.

The Benefits Of Porsche’s Braking Technology

In absolutely basic terms, by focusing on regenerative braking as the “primary,” and hydraulic brakes as “the assist,” the Taycan is extremely good on its brake discs and pads in terms of wear. The whole thing about electric motors used in cars is that they are “brushless,” meaning that there is no physical contact between the inner and outer coils, instead using electromagnetic fields to accelerate and decelerate the car. With the hydraulic brakes only really being used at ultra-low speeds under 10 MPH, as the magnetic field is not strong enough on its own at that point, and then only as needed depending on braking demands, they are able to last years without wearing down the pads or discs.

As well, being a German car that was partially developed on a very famous freeway system known as the Autobahn, the car’s regenerative brakes work better, naturally, the faster the car is going. It reaches maximum effectiveness at between 80 to 90 MPH (~140 KPH according to Porsche), which in most countries around the world is above the speed limit, even on the freeway. After that point, from 90 MPH to the top speed of 160 MPH, the hydraulic brakes will be used in an exponentially increasing manner to help slow the car down back to the efficiency curve where the regenerative braking will take over.

The Innovations (Potentially) Coming With The Next Taycan

For a while now, the Taycan has been the “hero car” for regenerative braking at Porsche. Now, however, the all-electric Macan is almost on the roads, and a performance hybrid version of the current Type 992 911 is rumored to be only a year or so away, both of which will feature the next generation of the blending technology.

It can be safely assumed, then, that the next refresh or sub-model of the Taycan will, of course, also be coming with that next generation of the system. While there are a lot of subtle winks and hints coming out of Stuttgart, no really solid information has been fully distributed. We can, however, state what is “all but confirmed” to be coming.

The biggest step is that the next generation of Porsche drive motors will very likely have a higher speed efficiency point, in the range of 100 to 120 MPH, as while the Taycan can be taken onto a track for some fun, a 911 is meant to take part in some “spirited driving,” as it were. This increase in the efficiency point will likely mean more powerful motors, increasing the overall equivalent horsepower that a Taycan can have, although it will probably be limited to the “Turbo S” top tier models.

Miniaturization and faster computers are the next major step, as computer technology has been exponentially getting more efficient, with smaller components and longer battery life, since the start of the century. Look at your smartphone, for example. Even 10 years ago, whichever brand you liked had a less powerful screen, would last maybe a day on a battery charge, and was somewhat slow. In 2023, the amount of chips, circuits, and power that your old phone used can be found in a smartwatch three times over, and that watch will last a week on a charge. Smaller, lighter, but more powerful computers in a car can only mean lighter weight and better processing of driver inputs.

While there is a lot of conjecture, what can be said with confidence is that no matter what, the Taycan is, if you discount the hypercar market, still the best electric car money can buy in 2023, and will likely remain at the top of the field for many years to come.

We never asked for it and we still don’t want it. All we wanted was analog sports cars but since the VW takeover, all that went to trash and all the good old analog buttons and hydraulic steering got replaced with feel-less VAG electric parts if low quality. Such compromised cars are good for rich Dummies, not for intelligent people who have brains to analyze what they need in their car.

I’d rather have the 997/987 as my car because those were last real Porsches. Later it was all ruined by VW. They might as well call them VWs now that Porsche family has not controlling rights anyway. Why misuse the name.

0

It’s hard to understand why Porsche can’t remain “Porsche,” and let VW deal with the electric stuff that leaves us all disappointed. Don’t worry…you’re not the only one with those feelings.

0