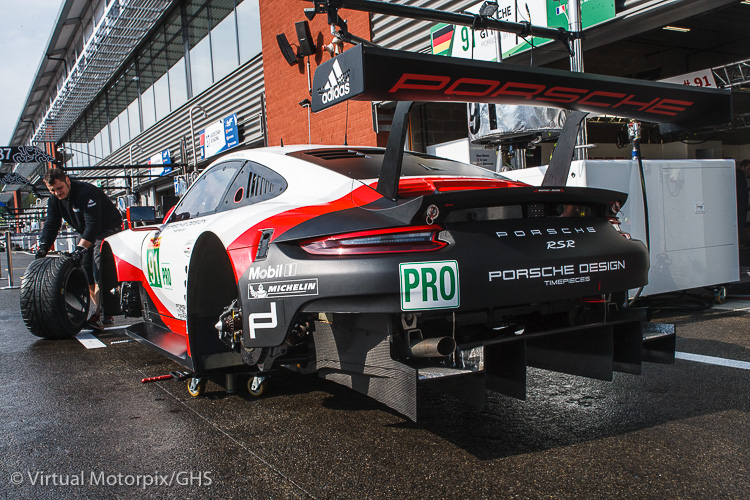

It was a long time in coming, or so it seemed, but when the 2017 Porsche 911 RSR was unveiled at the LA Auto Show on 16 November 2016, there were many who could not believe what they saw. A 911 with its engine turned around 180° and with the gearbox located behind the engine. The Porsche engineers were quick to point out that this was not a mid-engined 911, but rather a 911 with the engine located ahead of the rear axle. It didn’t take long for folk to realise that this was marketing speak as Porsche did not want to muddy the waters for those die-hard rear-engine 911 supporters. No matter where the engine was located it was a case of, all change.

The new 911 RSR’s first race was the Daytona 24 Hour on 28/29 January, and all eyes were on the 911. Driven by Patrick Pilet, Dirk Werner and Frédéric Makowiecki, the #911 car finished a very close second to the class-winning Ford GT. The Sebring 12 Hour followed on 18 March, and here the two works cars finished in seventh and eighth places, but still on the same lap as the class-winners, such was the closeness of the competition. The #911 Porsche is currently leading the Tequila Patron North American Endurance Cup GT Le Mans Teams table. This is a ‘championship within a championship’ if you like, where the four longer races, Daytona 24 Hour, Sebring 12 Hour, 6 hours of the Glen, and the Petit Le Mans 10 Hour race (Atlanta) – all in all, 52 hours of endurance racing, count towards this Cup.

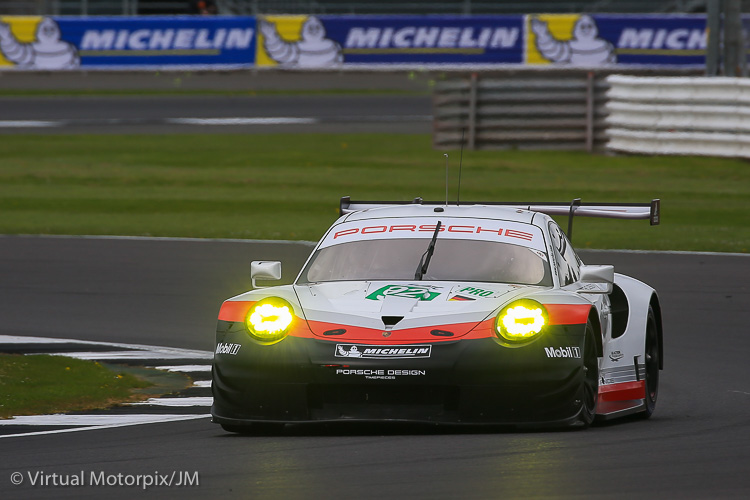

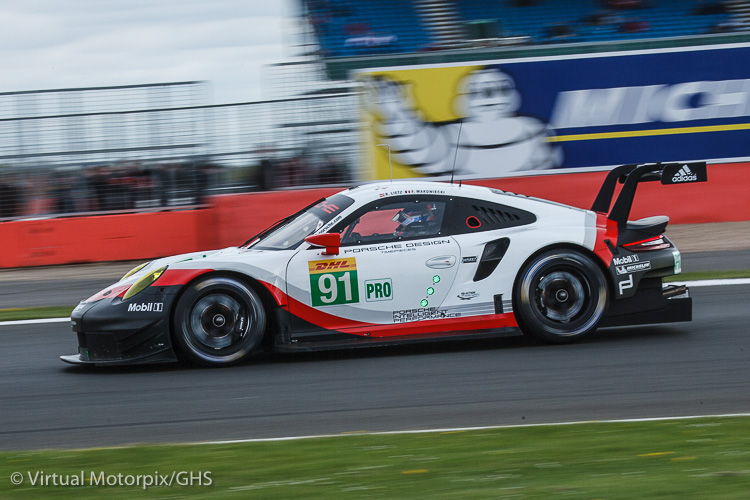

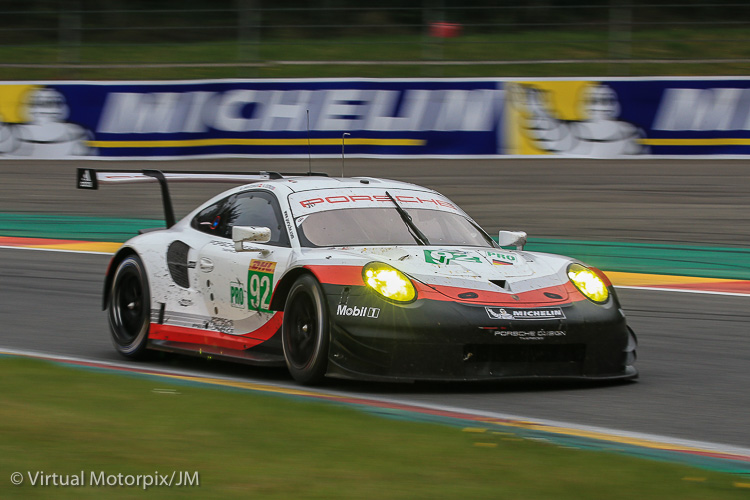

Over in Europe, the first race of the WEC season kicked off at Silverstone on 16 April where the two works 911s qualified in seventh and eighth places, effectively second last and last in class. The #91 driven by Richard Lietz and Fred Mako came home third in class which was an encouraging start to the WEC season. The second race at Spa on 7 May saw the two 911s finishing in fifth and sixth places. Next on the calendar was the Le Mans 24 Hour, which had not been that kind to the 911s in 2016. It was a somewhat disappointing result as the #91 car driven by the experienced trio of Richard Lietz, Fred Mako and Patrick Pilet finished fourth after a late puncture. The fourth round of the WEC at the Nürburgring brought a better result for the works 911s as the two cars finished second and third in class after Michael Christensen and Kevin Estre put the #92 car on pole for the start. This was only the second pole position start for any of the 911 RSRs since their introduction to the WEC back in 2013.

In an in-depth interview with Porsche Road & Race, Marco Ujhasi, Porsche’s Overall Project Manager GT Works Motorsport, explained the workings of the new 911 RSR:

Can you outline the brief that was given to you and when did this start?

The starting point is usually three years before you want to be out on track, and so in this case we started in about 2013 to make notes on what we would change if we could start from zero. Then the more detailed phase which included some conceptual work, was about 1 1/2 years before we wanted to be on track, so we started with this in 2015 just after Le Mans, which is usually a good starting point for new things.

This is not just a car based on the regulations, as we also needed to bear in mind what our road cars offered and we had to modify that with the regulations, which by the way, were not fixed at that point. So, there are many variables, and you can imagine you have to keep a lot of things in mind during the construction phase.

You also have to plan when you want to be on track, so you have to schedule [in advance] when you want to start because at a certain point you have to begin producing the parts [for the car]. So, you want to build in some margin in case something goes wrong. The roll out is the most important milestone in the project because from that you want to evaluate to see if all your thoughts and calculations were right, and it all really works for the driver. That is basically the process behind it.

This is a completely new concept, so what genes could you carry over from the old car?

Well, it is not completely new. The easiest thing to carry over was the spirit of the 911 and you will know that the founder of the company said that he couldn’t find the car that he was dreaming of, so he decided to build it himself, and so we did exactly the same. We started with a very good road car as the base, and we tried to fulfil the promise our engineers gave to the company, to always make the best 911 for a certain purpose. We were allowed by the technical regulations to move the engine because that was key to building a new, modern generation GT car. Because the aerodynamics are now even more important, we needed a rear diffuser and you also have to do double stints with the new WEC regulations, and so we had to look after the tyres. This is the reason why we had to make such a big step, to make life easier for the driver and to double stint your tyres, otherwise you would have no chance to build consistency.

We did not have to add that much to fulfil all the safety requirements, because our tub is very good in a crash situation, even without the roll cage. The front and the rear are quite good because a lot of deformation is possible, but from the side it is quite difficult [to protect the driver]. For that reason, we moved the seat to the middle of the car as much as possible, to ensure there is sufficient space to absorb the energy in the structure. But from a certain point on, you just have to protect your driver and not absorb any more energy, so this is then the point where the roll cage comes in. The roll cage is like a monocoque around the driver, but it is not made from carbon fibre, it is made of steel.

When you decided to turn the engine around 180°, how was this taken by the others within Porsche?

It’s a bit of a funny story. We just did it, and when it was done and it looked good and everybody was confident that it would work, then we told the others. The heritage of the 911 is to make the best product for the purpose for which you are using it. This is for me the reason the 911 has survived for such a long time.

Did you make any design changes to accommodate the new engine position, because the engine must push into the cabin a bit?

It was quite simple to accommodate the new engine position, because we have very good modules in our production cars. I have not calculated the number, but I would say from the structure, we have retained about 85% of the road car.

What is the weight distribution of the old versus the new car?

It is a favourable change.

Because of the change in weight distribution, the new RSR must have required quite different settings. Can you say what you did?

The changes are not mainly related to the weight distribution. We decided to stay with the double wishbone on the front which we have had on the car since 2013. On the rear axle, the new regulations allowed us to stay with the original layout, or to go to a double wishbone setup. And we decided to go with a double wishbone on the rear axle. So, we have no more multi-link suspension on the rear and the reason for that is that it is easier to handle at the track. The setup changes are quicker, and changes on one parameter don’t influence the other parameters that much.

Is the RSR homologated on the GT3?

Yes, the homologation model is actually the GT3 RS, and based on the technical regulations, you can modify the wheelbase and so on, and so we went to the maximum on all the dimensions.

Is there an overall aerodynamic improvement figure for the new car over the old?

It is better for sure. If you look at all the new GT cars, the Ferrari, Corvette, Aston Martin and Ford, they are all quite close together. You can see this from the geometrical dimensions, so they are all in the same range now. In 2016 with the old car, we were definitely not in that range. The biggest factor though is the diffuser, now we have a proper diffuser.

Can you expand on the advantages of the new diffuser?

The most important for a race car is that you achieve a certain balance, because balance is always the key for the driver to handle the car. This balance is made up of an aerodynamic balance and the mechanical balance, and they are related to each other. The more flexibility that you have with the aerodynamic balance, the more flexibility you also have with the mechanical balance.

On the other hand, in a modern GT car you need as much downforce as possible and this is the link to the car’s balance. You can generate a certain amount of downforce at the front and rear, and this is in a certain relationship. But if you can generate more on the rear you can generate more on the front and the other way around, and that defines your maximum. The most efficient way to generate downforce on the rear is with the diffuser and you want this because the aerodynamics that you can generate from the underfloor is more efficient than what you can make with the airflow above the car. So, you want to accelerate the air at the front and this you do when you have a small gap between the front lip and the road, and a bigger gap between the floor and the road at the rear. This creates the downforce on the front axle, which starts on the front with the highest level and gets less and less towards the rear. But you need a good rear diffuser for good front axle downforce. Not everyone knows, but the diffuser creates downforce on the front axle, not on the rear!

The side mirror stalks also help with the airflow around the side of the car I believe.

Yes, it improves the airflow around the car, but more important is how you can influence the airflow to the rear wing. The rear wing is very important and you want to have clean air flowing to the rear wing. And everything that helps the airflow to the rear wing is highly welcome.

Can you outline some of the key testing stages on the way to the roll out?

The roll out is a very big step in such a project because that is the first time where you are bringing all the components together. Here you will have your first impression of all the components really working together from a functional standpoint. The good thing for us was that it worked so well that we were not just cruising round, but we were able to put all of our factory drivers in the car, and give them some laps on the proving ground.

At the roll out I would say we did 30 to 40 laps which is quite impressive with a brand-new car, and the drivers immediately said it felt just like a 911, but a better one. If you can achieve this on the first roll out, that is definitely a very good thing because then you know all your calculations were right and all the ideas that you put into the car were right, so we were quite happy with that feedback. After that, and this is also an important stage, it is not just about driving but also analysing what happened at the first roll out. The next stage is to analyse the data for maybe 5 to 10 days, checking all your calculations, and also validating your simulation model.

From that point, you can start to work on the performance side. The next steps are then on the reliability. And we did a lot of reliability testing quite close to Weissach because with a new car you never know what will happen. The knowledge from the previous model is worth maybe 20%, not more, and there you spend a lot of time in the beginning finding out if the car reacts to set up changes in the same way that the old car did. So, we were quite happy and confident that we could continue fairly quickly with some performance runs and performance improvements.

The second stage, performance wise, is to find the right solution to make the driver happy and to give him the right balance, this is the key to have quick lap times. We were happy with the baseline performance and so we continued with endurance runs which culminated in the 50-hour test at Sebring in late-October 2016. The 50-hour run at Sebring was with one car, just driving, refuelling, tyre changes and so it went, it was very impressive to see the car go. When we had finished the 50 hours, we looked at the car and someone said, jokingly, okay we can do another 50 hours because it still looked so good. We had no issues during those 50 hours, and so that was a very useful test. You try to do this endurance testing quite late because you need to achieve a certain performance level first in order to ensure a reasonable reliability test. But this means the time is quite short if you have to make some big changes to the car, because then you are in a big hurry to get ready for Daytona.

Who was the first driver in the car at the roll out?

The roll out was done in early March 2016 at Weissach, and the first driver, if I remember correctly, was our 2015 champion, Richard Lietz.

What engine is the RSR engine based on?

This engine is based on the latest GT3 engine and it is now part of the GT engine family because the GT3 R, the race car, is also running that engine. The only changes are based on the regulations, as some things are allowed in GT3 regulations but not in GTLM or GTE. So, as from this generation, we are running direct injection in the RSR, this was the last car to implement this technology.

Sadly, the last year of the Mezger engine was 2016. If you look at the power per litre [of the Mezger engine], it was fantastic, and if you look at the weight of that engine it was a really good engine, but at a certain point you have to change, for instance to add the direct injection. And also, as from a certain point onwards, it is difficult to get some spare parts for the old engine, so there are also other reasons to change.

What gearbox is in the RSR, is it the same as before or a new one?

No, it is completely new. Because of the changes in the engine position, we had to redefine the gearbox and we also wanted to realise the maximum wheelbase allowance by the regulations, so it was necessary to design a new gearbox. We wanted to go one step further with a shifting actuator, and we decided at a very early stage to go to a shifting barrel. This is an electromechanical setup and we are very happy with it, and the drivers say that it is one of the big improvements from the old car to the new car. For weight reasons, we went for a magnesium gearbox housing.

If you have an engine problem mid-race, how do you access the engine?

It depends on what problem it is. The usual ones you can fix, but for bigger things you cannot change anyway, so it is no worse than before. We can reach some components from inside the car, through the rear window and we also can do it from the underfloor. So, we are quite happy with all the normal things that you can do and it doesn’t take longer than with the old car.

The engine change is also very quick if you have to do this between sessions, so we are quite happy with the service concept. We wanted to improve the serviceability from the old to the new car, because on a race weekend you need every second on track as well as rest times for the mechanics. So that was a big task for us to make this happen.

The rear windscreen panel is not transparent, is that not a disadvantage for the driver?

No, you cannot see anything through there anyhow, so it doesn’t make any difference. We also implemented a collision avoidance system so we have a big screen inside and this gives a better view than just looking through the mirror, and so that is fine.

The balance of the car, is this something that is now sorted?

If you go racing for the first time with a completely new car, and then you add the requirement to double stint the tyres, this is even more complicated. At Silverstone we were okay, but at Spa it wasn’t that good. If you look at the USA, we have been quite competitive in every race so far with the same car, so I have no doubt that we have a really competitive car. We have to learn and we have to improve and to understand that in certain situations the car could be a bit better. But this is a normal learning process and honestly nobody expected that we would have perfect races around the world.

What was the most satisfying aspect of this project for you?

The most satisfying was seeing all the people working together and it’s not just the engineers, it is the mechanics, the drivers, the management and everybody was on fire for that project. If you can work in that environment, it is amazing. To go through all the development steps and then after that to go to the Daytona 24-hour race, finish the race with two cars and with a second-place, that was really amazing for sure.

Conclusion

With almost half of the 2017 WEC season now behind us, the Porsche GT team is languishing down in fourth (last) place in the GT FIA World Endurance Manufacturers’ Championship. But their tally of 106 points is only 29 points behind class leaders Ferrari who have 135 points. The situation might at first glance appear dire, but there are still five races to go in the season. The new computerised BoP index which was applied as from the last race at the Nürburgring, saw the new RSR take its second pole in almost five years, all of which bodes well for the rest of the season.

Written by: Glen Smale

Images by: Virtual Motorpix/Glen Smale & John Mountney

2017 Porsche 911 RSR Explained

#92, Porsche Motorsport, Porsche 911 RSR (2017), driven by Michael Christensen, Kevin Estre during at FIA WEC 6 Hours of Silverstone 2017, Silverstone International Circuit, on 14.04.2017